1. Product Overview

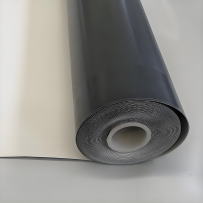

Atactic Polypropylene (APP) modified bitumen waterproof membrane is a high-performance waterproofing material produced by modifying high-quality bitumen with APP thermoplastic resin. It is reinforced with polyester felt or fiberglass to enhance tensile strength and dimensional stability. This membrane exhibits excellent high-temperature resistance, strong adhesion, and superior waterproofing performance, making it ideal for various roofing and underground applications.

2. Key Features

• Exceptional Heat Resistance: APP modification enhances the membrane’s resistance to high temperatures, preventing deformation or flow in hot climates.

• High Tensile Strength: Reinforced with polyester or fiberglass, providing outstanding mechanical strength and durability.

• Superior Waterproofing Performance: Ensures a completely watertight system with excellent resistance to water penetration.

• Strong Adhesion: Bonds well with concrete, metal, and wood surfaces, ensuring long-lasting waterproofing.

• Aging and Weather Resistance: Excellent resistance to UV rays, ozone, and oxidation, ensuring a long service life.

• Multiple Installation Methods: Can be applied using the torch-applied method or hot-melt application, offering flexibility in construction.

3. Applications

• Waterproofing for industrial, commercial, and residential building roofs.

• Underground waterproofing for basements, tunnels, and subways.

• Bridges, highways, and railways requiring waterproofing protection.

• Water retention structures such as reservoirs, dams, and water treatment plants.

4. Installation Process

1. Surface Preparation: Ensure the substrate is clean, dry, and free from dust, grease, and loose materials.

2. Primer Application: Apply a bitumen-based primer to improve adhesion between the membrane and the substrate.

3. Membrane Installation:

• Torch-Applied Method: Use a propane torch to heat the membrane’s underside while unrolling it onto the surface.

• Hot-Melt Method: Apply hot bitumen adhesive before laying the membrane.

4. Seam Treatment: Overlap adjacent membranes and heat-weld or adhere them to form a seamless waterproofing layer.

5. Quality Inspection: Conduct adhesion and waterproofing tests to ensure proper installation and long-term durability.