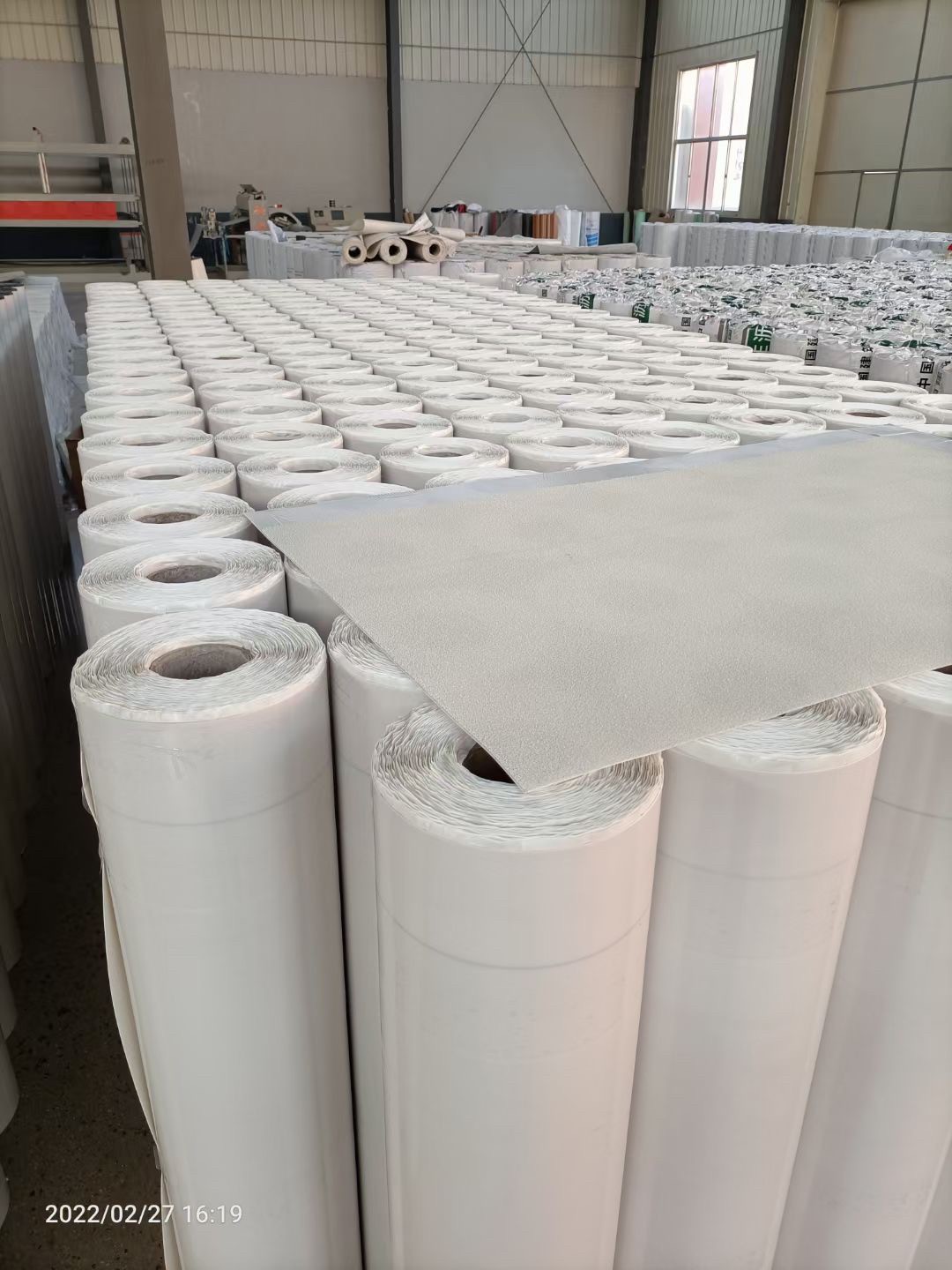

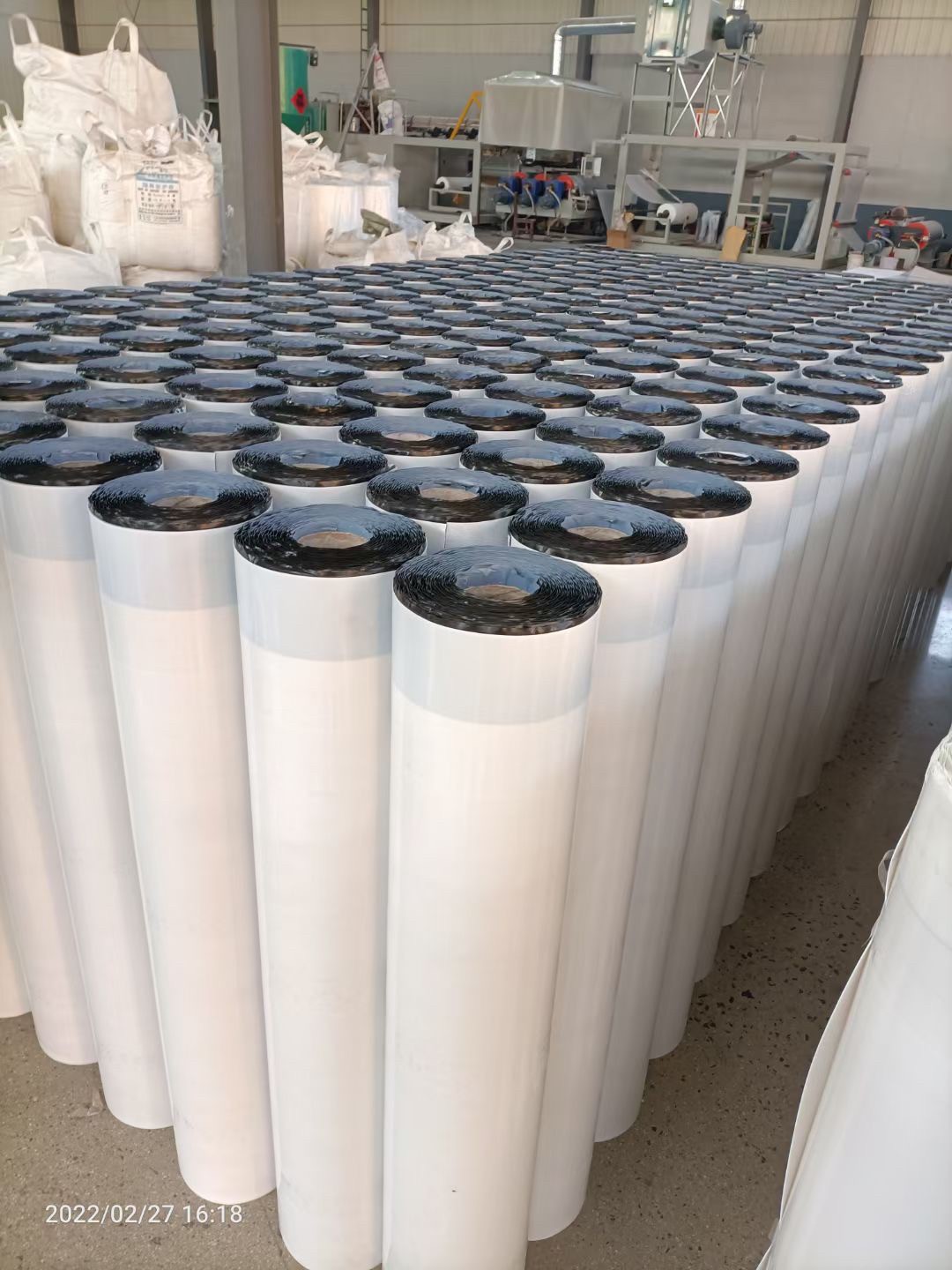

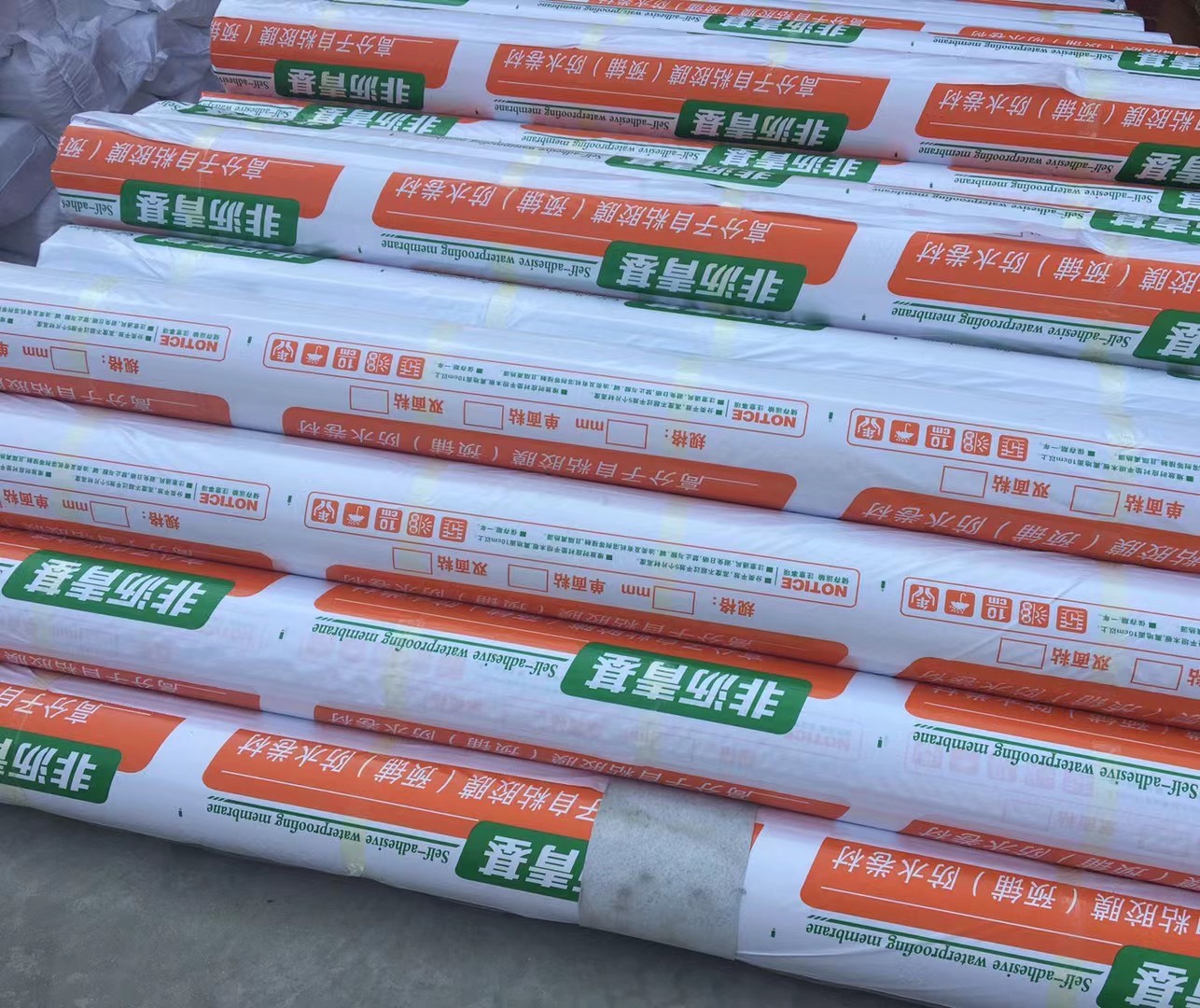

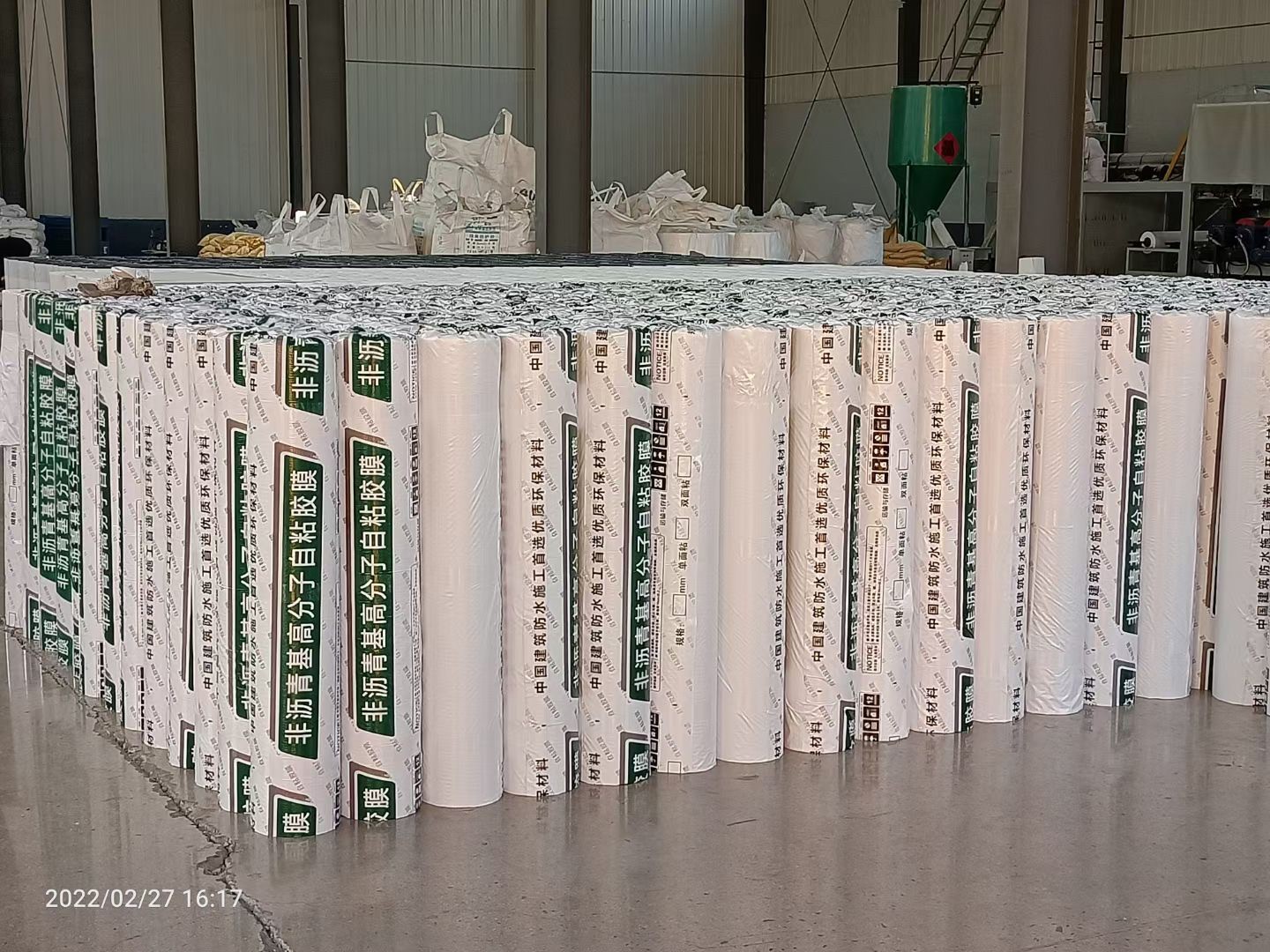

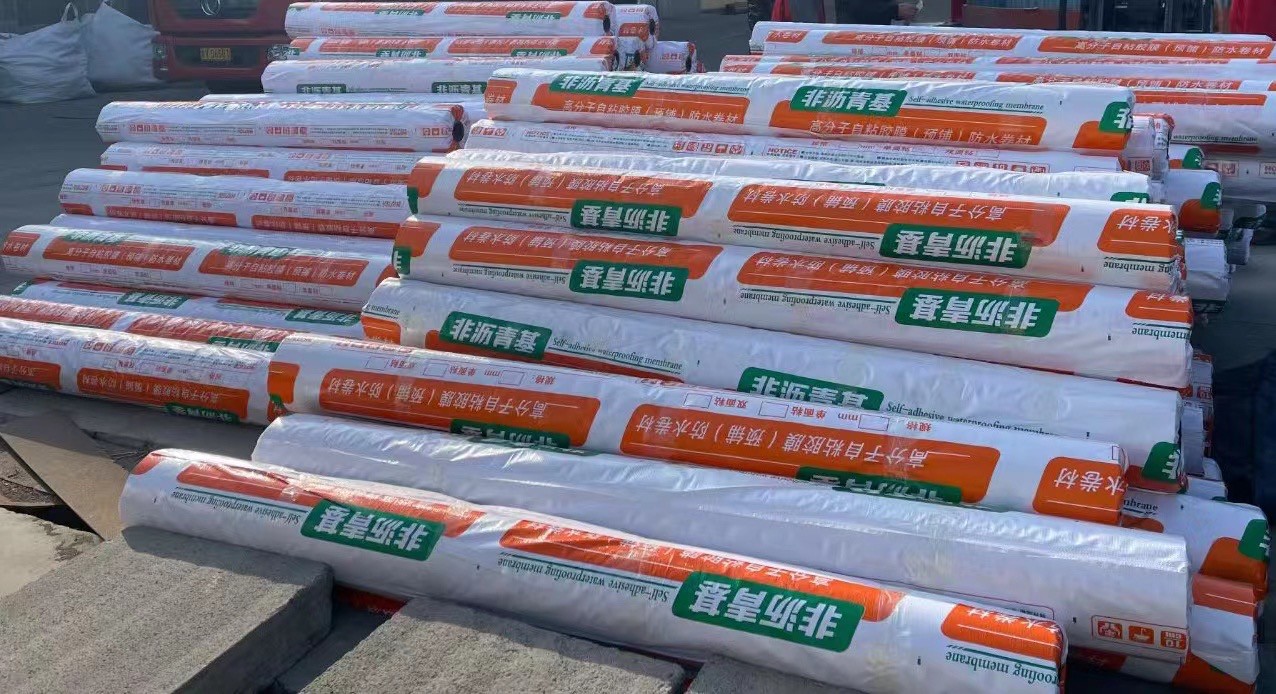

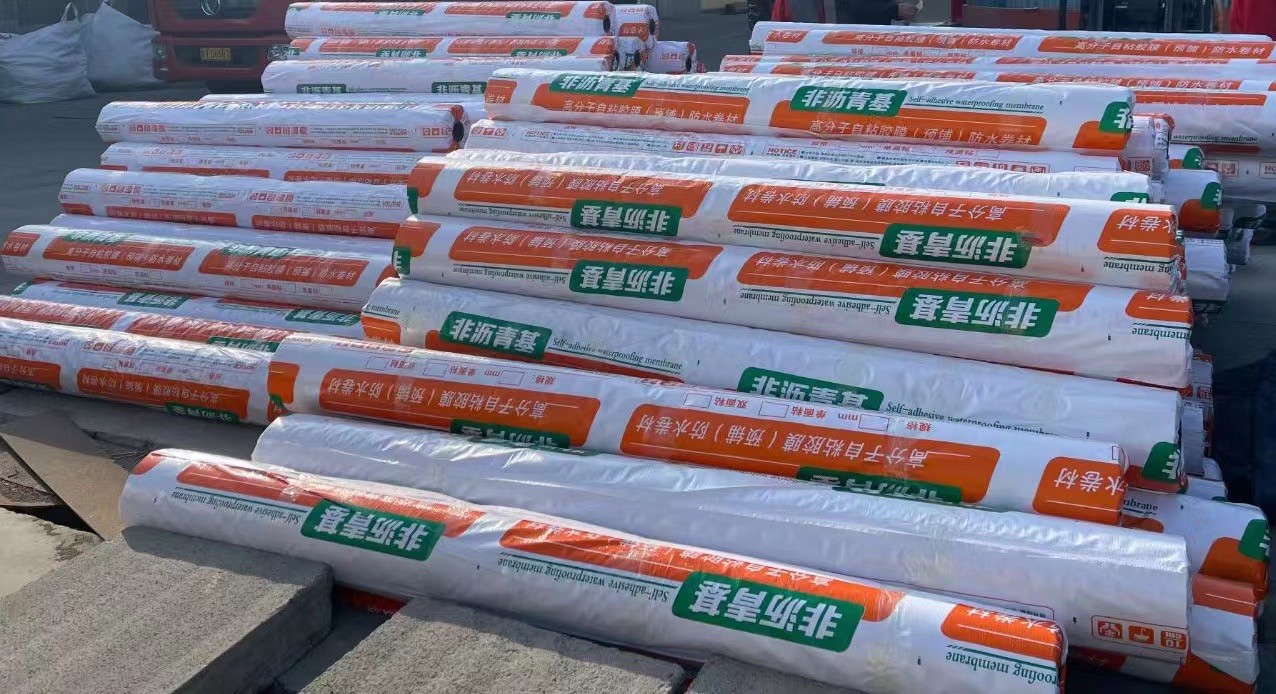

1. Product Overview

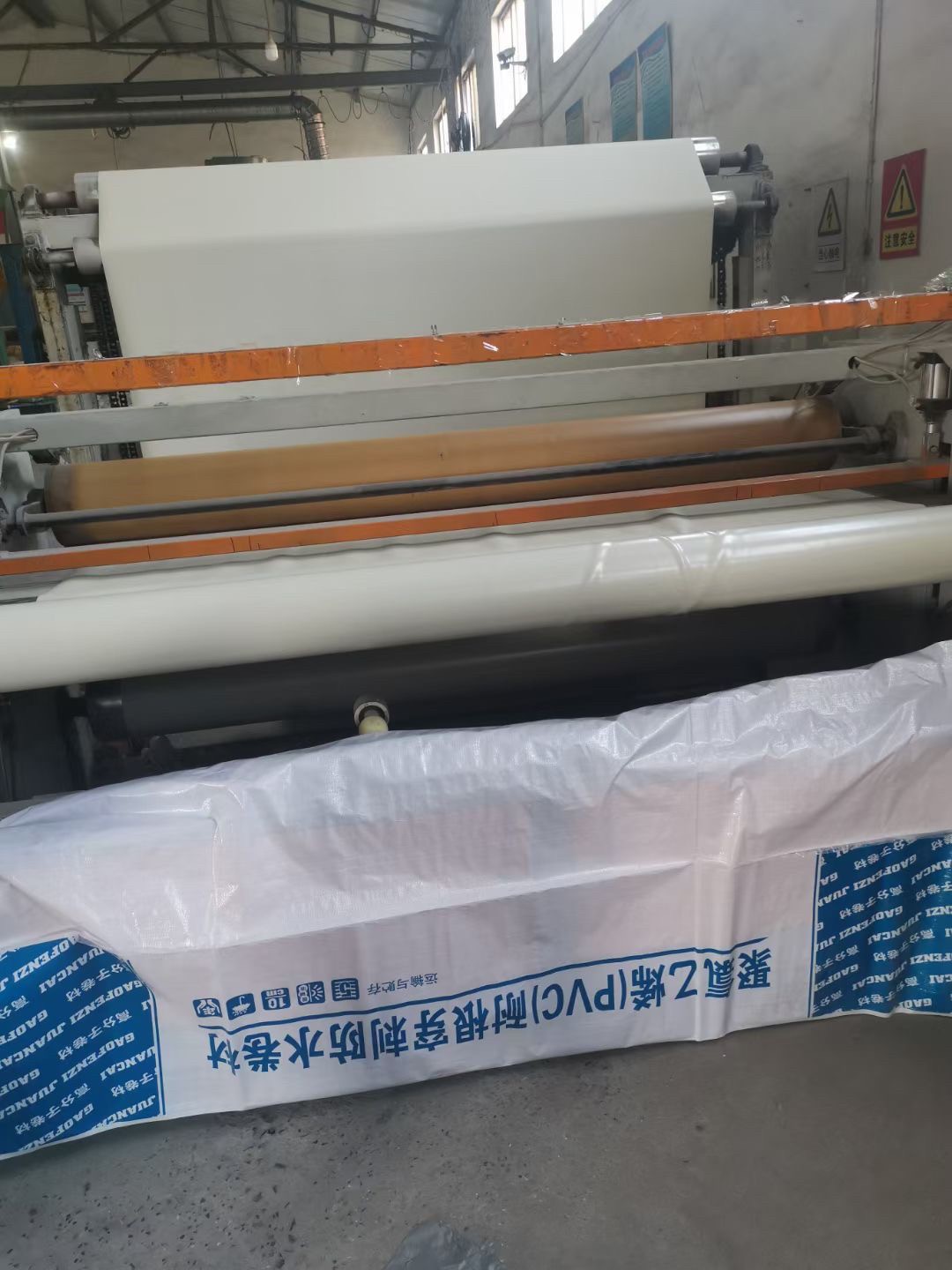

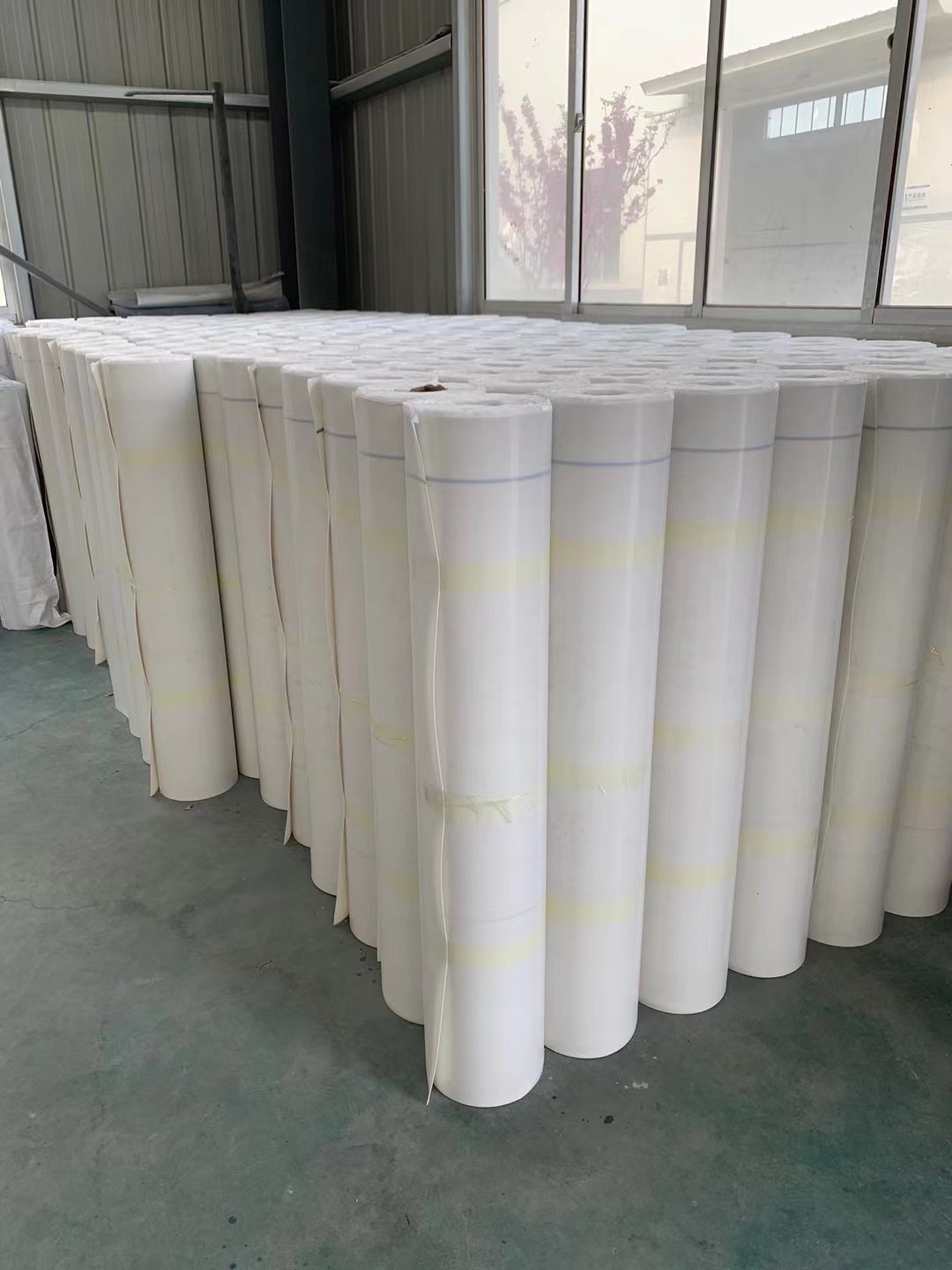

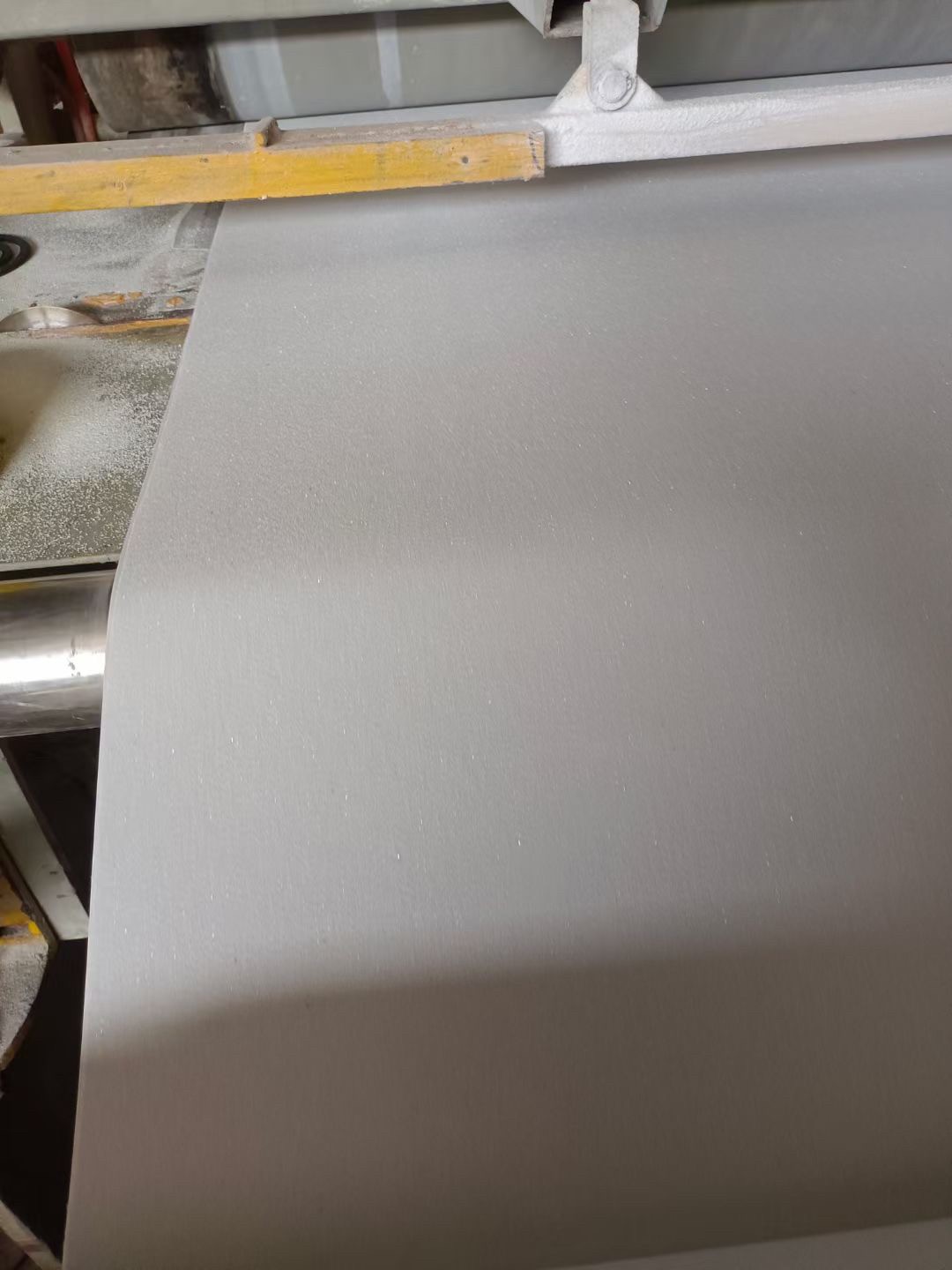

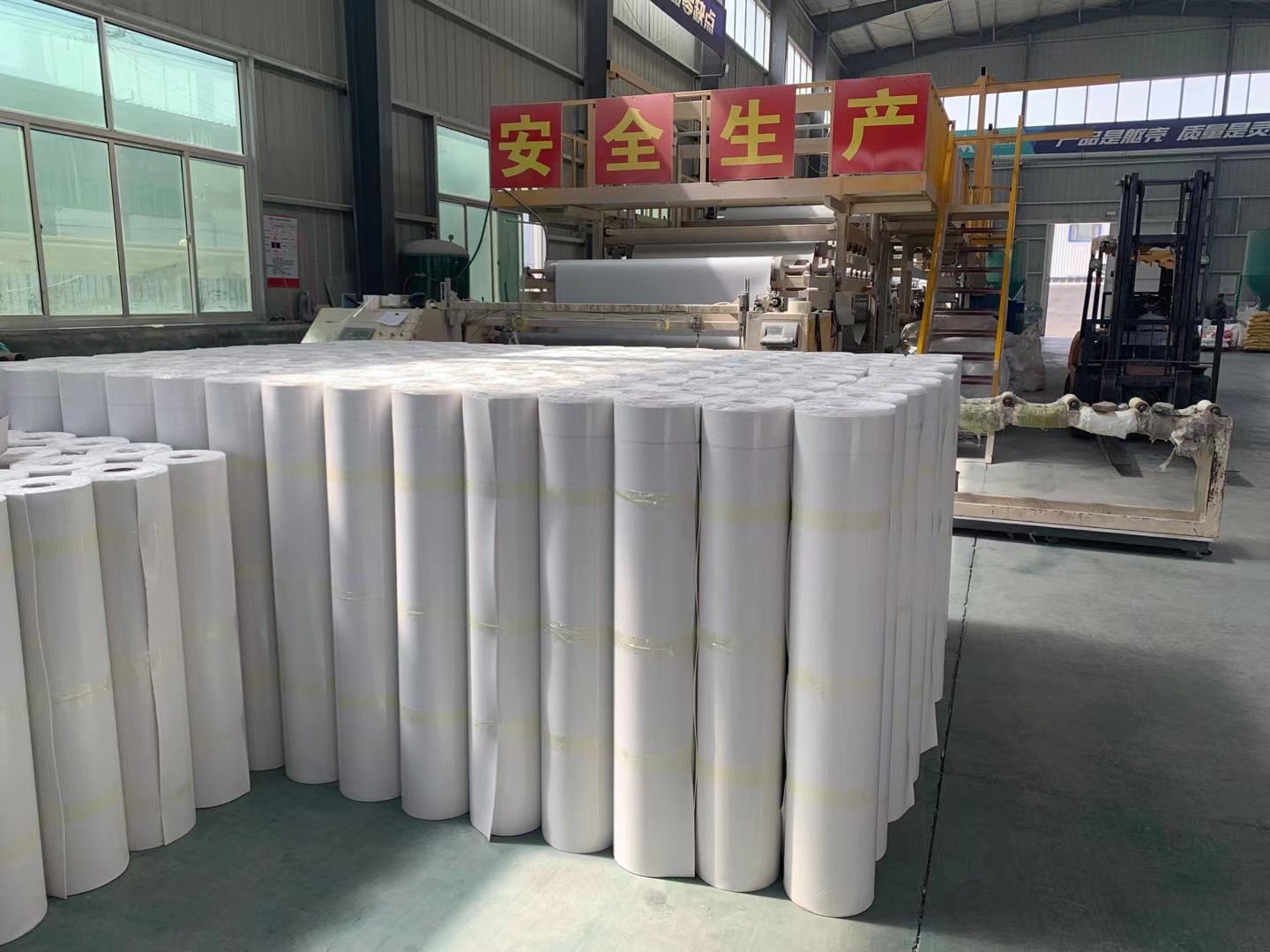

The pre-applied/wet-applied waterproof membrane is an advanced waterproofing material designed for efficient and reliable application in underground and structural waterproofing projects. It is composed of high-quality polymer-modified bitumen and reinforced with a high-strength polyester or fiberglass mat. This membrane is specifically engineered for pre-applied (before concrete pouring) and wet-applied (applied to a wet substrate) installation methods, ensuring a strong bond with concrete structures and preventing water infiltration.

2. Key Features

• Excellent Waterproofing Performance: Provides superior resistance against water penetration, ensuring long-term durability.

• Strong Bonding with Concrete: Forms a tight and permanent bond with poured concrete, preventing water migration.

• Adaptability to Complex Structures: Can be applied to various structural surfaces, including irregular and vertical surfaces.

• High Tensile Strength and Flexibility: Reinforced with polyester or fiberglass, offering excellent mechanical performance and flexibility.

• Self-Healing Properties: The bitumen layer can self-repair minor punctures and damages, enhancing the waterproofing effect.

• Cold-Applied Technology: No need for heating or torching, making installation safer and more environmentally friendly.

3. Applications

• Underground structures such as basements, tunnels, and subways.

• Waterproofing for foundations and retaining walls.

• Bridges, highways, and railway structures requiring long-term waterproofing.

• Industrial and commercial buildings requiring efficient and durable waterproofing solutions.

4. Installation Process

1. Surface Preparation: Ensure the substrate is clean and free from sharp objects, dust, and excessive moisture.

2. Primer Application (if required): Apply a bitumen-based primer to enhance adhesion when necessary.

3. Membrane Installation:

• Pre-Applied Method: Lay the membrane with the adhesive side facing upwards before concrete pouring.

• Wet-Applied Method: Apply the membrane directly to the wet substrate, ensuring full contact and adhesion.

4. Seam Treatment: Overlap adjacent membranes and ensure proper sealing to form a continuous waterproof layer.

5. Concrete Pouring (for Pre-Applied Method): Once the membrane is properly placed, pour the concrete directly onto it to create a strong bond.

6. Quality Inspection: Conduct adhesion and waterproofing tests to ensure proper installation and durability.