1. Product Overview

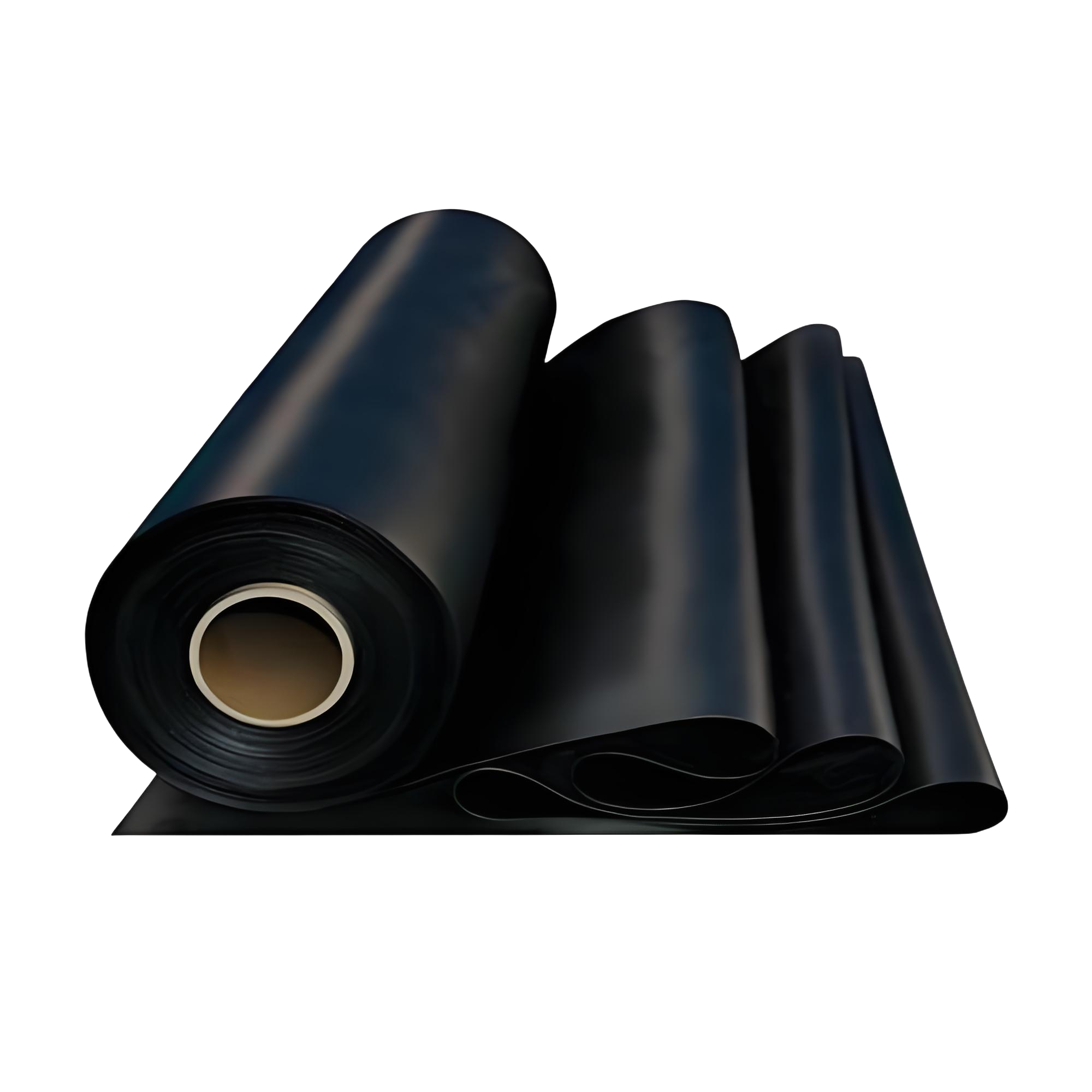

Ethylene Propylene Diene Monomer (EPDM) Waterproof Membrane is a highly durable, synthetic rubber roofing membrane known for its excellent waterproofing properties. It is made from a combination of ethylene, propylene, and diene monomers, resulting in a material that offers superior resistance to environmental factors such as UV rays, ozone, and extreme weather conditions. EPDM membranes are ideal for flat and low-slope roofing applications, as well as for use in foundations, basements, and other critical waterproofing needs.

2. Key Features

• Durable Synthetic Rubber: Provides outstanding long-term performance with high resistance to weathering, UV rays, and ozone.

• Superior Waterproofing: Ensures a strong and reliable barrier against water infiltration, preventing leaks and moisture damage.

• UV and Ozone Resistance: Withstands prolonged exposure to UV rays and ozone, making it highly suitable for outdoor applications.

• Flexible and Elastic: Maintains flexibility and elasticity in varying temperatures, allowing it to adapt to building movement.

• Environmentally Friendly: EPDM is non-toxic and can be recycled, offering an eco-friendly option for waterproofing.

• Low Maintenance: Requires minimal maintenance and retains its performance over time without cracking or degrading.

3. Applications

• Roofing systems, particularly for flat and low-slope roofs.

• Foundation and basement waterproofing.

• Waterproofing for ponds, tunnels, and reservoirs.

• Sealing for joints, seams, and penetrations.

• Suitable for both residential and commercial applications.

4. Installation Process

1. Surface Preparation: Clean and dry the surface thoroughly, ensuring it is free of debris, dust, and contaminants.

2. Roll out the Membrane: Unroll the EPDM membrane onto the prepared surface.

3. Adhesive Application: Apply the adhesive to both the surface and the back of the membrane for secure bonding.

4. Position and Press: Position the membrane accurately and press it down firmly to ensure adhesion.

5. Sealing Joints: Overlap adjacent sheets and use appropriate seam treatments (such as heat welding or adhesive bonding) to form continuous, waterproof seams.

6. Inspection: Conduct a thorough inspection to ensure the membrane is correctly applied with no gaps or air pockets.