1. Product Overview

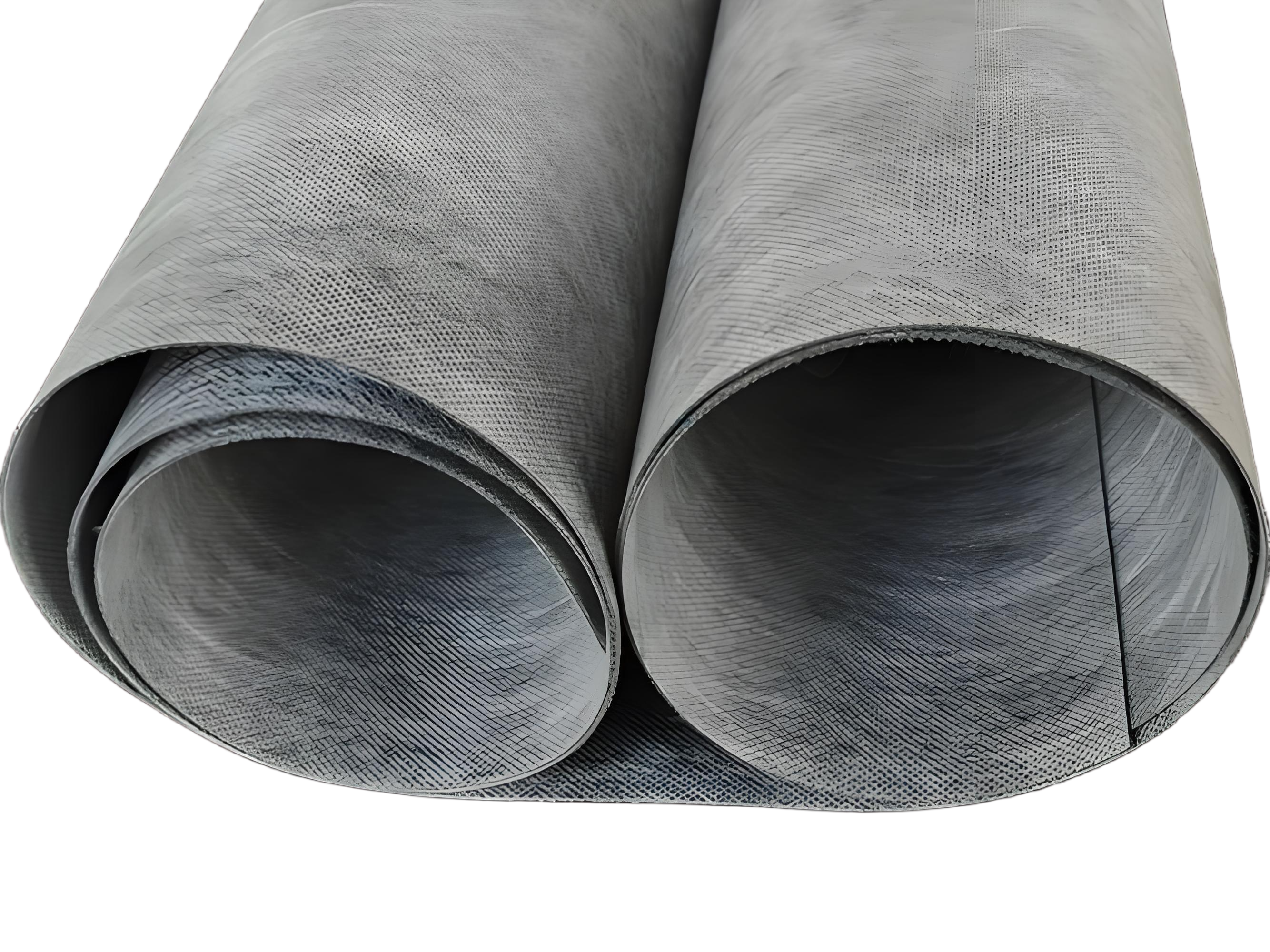

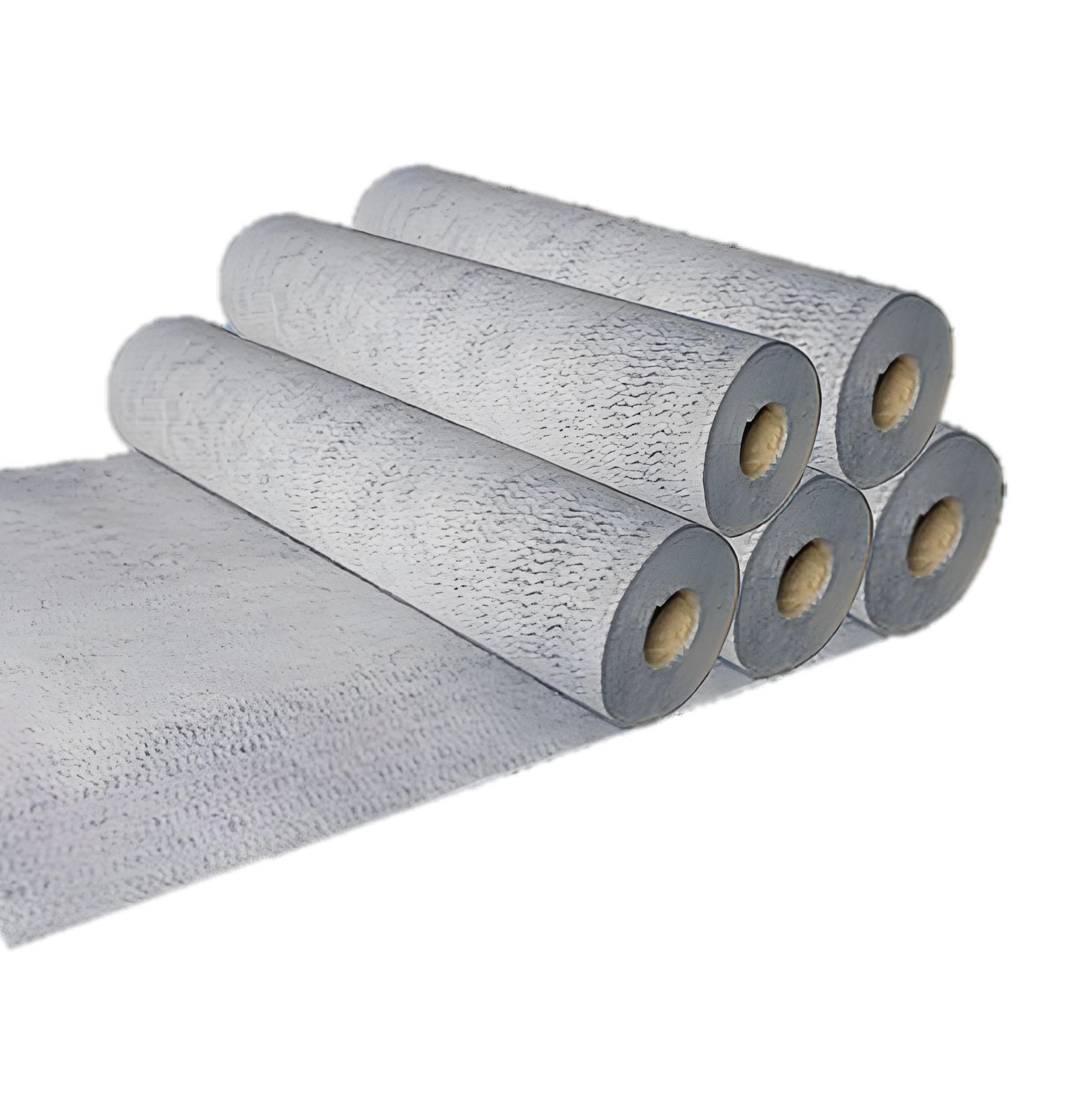

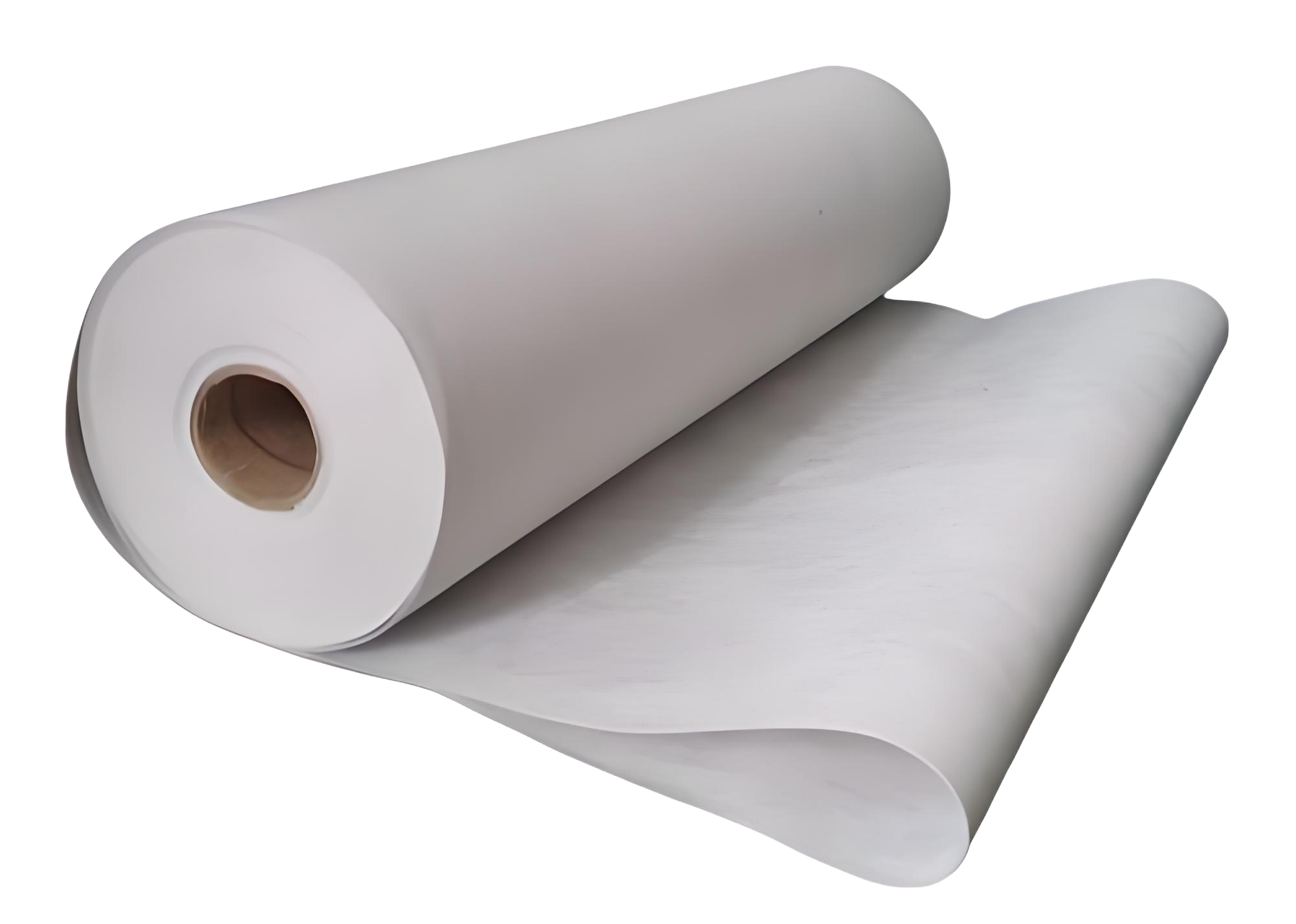

Polyethylene and Polyester Polymer Waterproof Membrane is a high-performance waterproofing material composed of a combination of polyethylene (PE) and polyester fibers, designed for superior waterproofing applications. The membrane is highly resistant to water penetration, UV degradation, and extreme weather conditions. Known for its excellent durability and flexibility, this membrane is widely used in roofing, basements, and other areas where a robust waterproof barrier is required. It is also lightweight and easy to install, making it suitable for a variety of applications.

2. Key Features

• Superior Waterproofing Performance: The combination of polyethylene and polyester offers enhanced waterproofing properties, preventing water infiltration effectively.

• UV and Weather Resistance: The membrane exhibits excellent resistance to UV rays, ozone, and extreme weather conditions, ensuring long-lasting protection.

• High Durability: The material is resistant to wear, punctures, and tears, offering robust protection against physical damage.

• Excellent Flexibility: Maintains flexibility even at low temperatures, allowing the material to adapt to structural movements and environmental changes.

• Lightweight and Easy to Handle: The membrane is lightweight, making it easier to transport and install, reducing labor costs and installation time.

• Environmentally Friendly: The materials used in the production of the membrane are eco-friendly and recyclable.

3. Applications

• Roofing systems, especially for flat or low-slope roofs.

• Basement and foundation waterproofing.

• Waterproofing for tunnels, bridges, and other civil engineering projects.

• Sealing for construction joints and cracks.

• Suitable for both new construction and renovation projects.

4. Installation Process

1. Surface Preparation: Ensure the surface is clean, dry, and free from debris, dust, and contaminants.

2. Unroll the Membrane: Lay the polyethylene and polyester polymer waterproof membrane onto the prepared surface.

3. Adhesive or Mechanical Fastening: Apply adhesive or use mechanical fasteners to secure the membrane to the surface, depending on the project requirements.

4. Sealing Seams: Overlap adjacent membranes and seal the seams using the appropriate sealing technique (adhesive, welding, or mechanical fastening).

5. Final Inspection: After installation, inspect the membrane to ensure there are no gaps, air pockets, or defects.