1. Product Overview

1. Product Overview

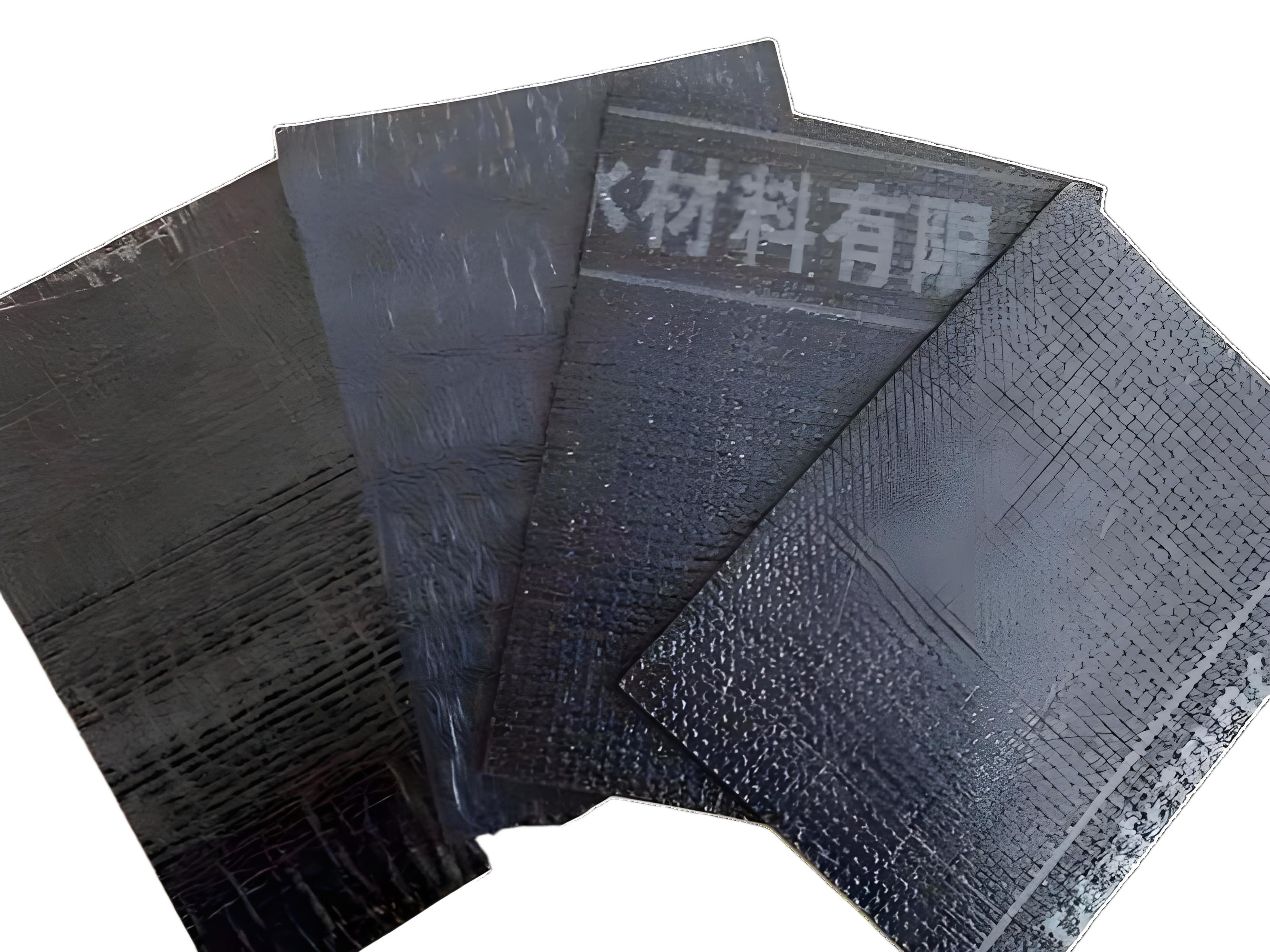

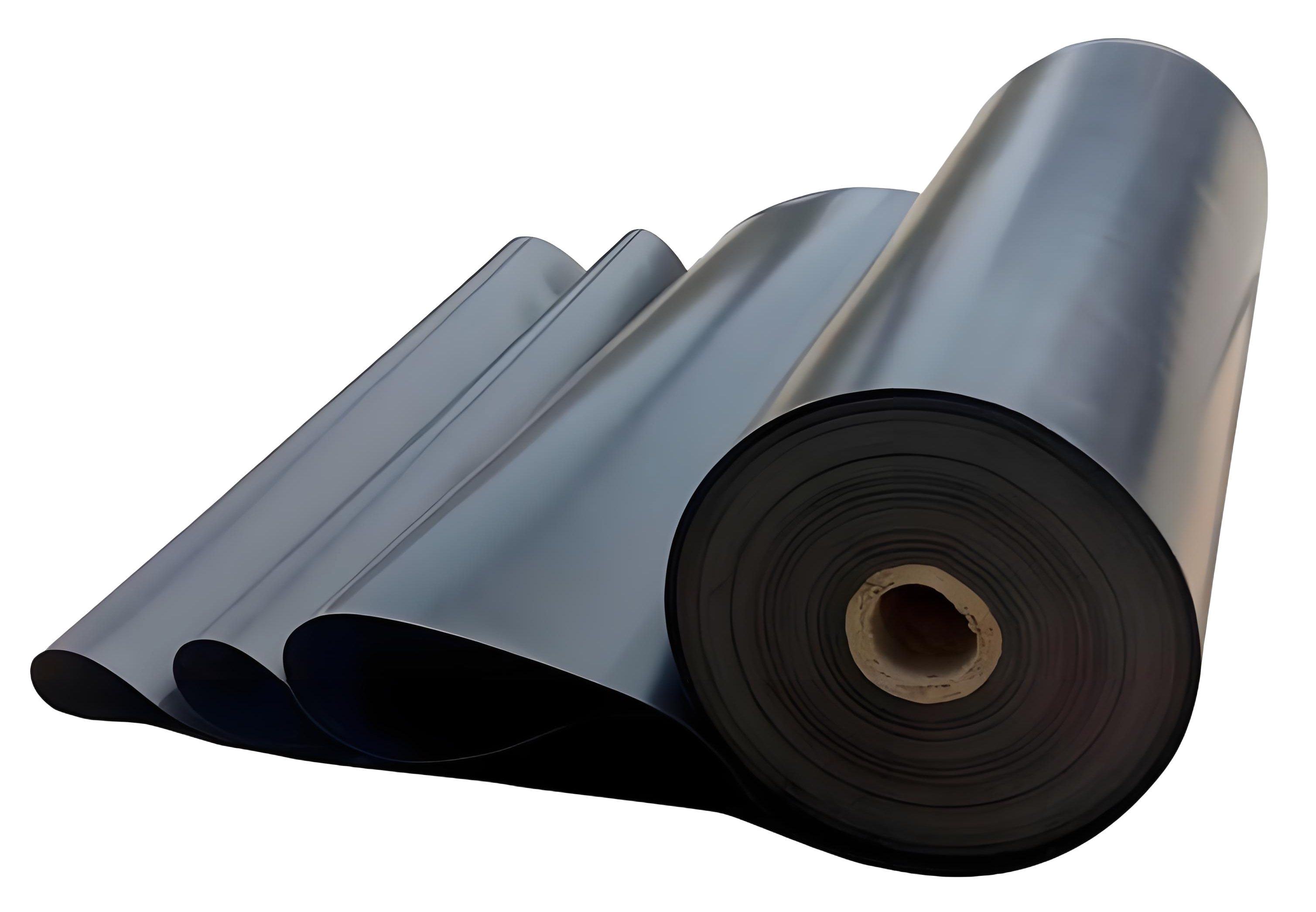

The Elastomeric/Plasticized Chemical Root-Resistant SBS Waterproof Membrane is a high-performance waterproofing material specifically designed to resist root penetration while providing superior waterproofing capabilities. Made from Styrene-Butadiene-Styrene (SBS) polymer, this membrane combines elastomeric and plasticized properties, offering excellent flexibility and resistance to cracking. It is specially engineered for green roofing systems, providing protection against root growth, water infiltration, and extreme environmental conditions. The membrane’s durability, flexibility, and root-resistant properties make it a popular choice for both residential and commercial waterproofing applications, especially in areas with plant growth.

2. Key Features

• Root Resistance: The membrane is chemically designed to prevent root penetration, making it ideal for green roofs and landscaping applications.

• Superior Waterproofing: Offers excellent waterproofing properties, ensuring reliable protection against water infiltration.

• Elastic and Flexible: The SBS polymer provides flexibility and elongation properties, allowing the membrane to adapt to movement and prevent cracks.

• UV and Ozone Resistance: Exceptional resistance to UV radiation and ozone, making the membrane suitable for outdoor exposure.

• Chemical Resistance: The membrane is highly resistant to chemicals, oils, and other environmental contaminants, ensuring long-term durability.

• Easy to Install: Simple and fast installation with the use of heat welding or adhesive methods.

• Environmentally Friendly: SBS is an environmentally friendly material that meets sustainability standards.

3. Applications

• Green roofing systems and rooftop gardens.

• Landscape waterproofing and root barrier applications.

• Waterproofing for parks, green spaces, and urban developments.

• Protection for terraces and balconies with vegetation.

• Suitable for both new construction and renovation projects.

4. Installation Process

1. Surface Preparation: Ensure the surface is clean, dry, and free from debris and contaminants.

2. Unroll the Membrane: Lay the elastomeric/plasticized SBS waterproof membrane on the prepared surface.

3. Adhesive or Mechanical Fastening: Apply adhesive or mechanical fasteners to secure the membrane depending on the project needs.

4. Seam Welding: Overlap the seams and heat weld them to create a strong, waterproof bond.

5. Final Inspection: Inspect the membrane to ensure there are no gaps, air pockets, or defects in the installation.