1. Product Overview

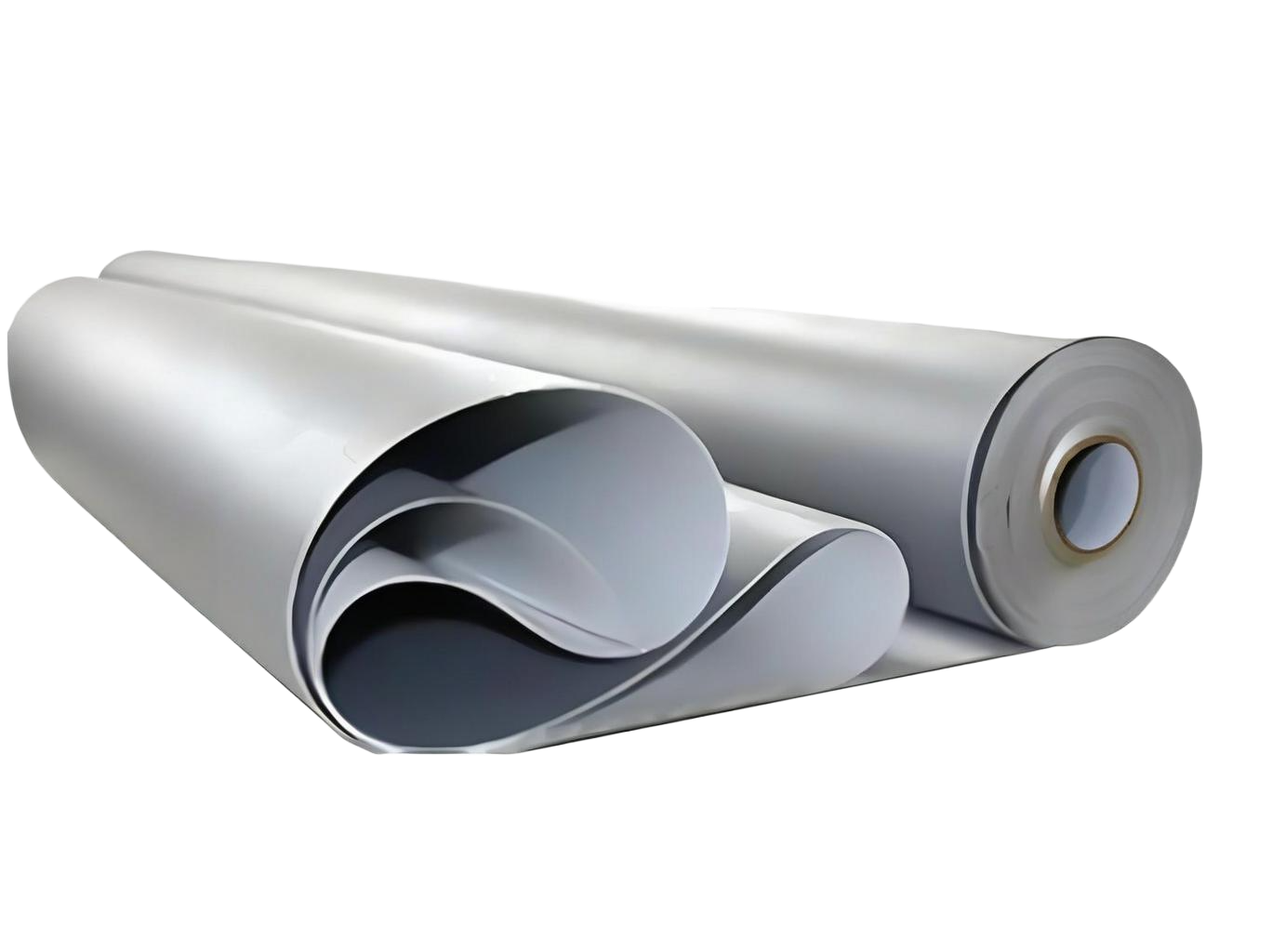

The Thermoplastic Polyolefin (TPO) Reinforced Waterproof Membrane is a high-performance waterproofing solution designed for use in a variety of construction applications, including roofs, walls, and foundations. TPO is a single-ply membrane made from a blend of polypropylene and ethylene-propylene rubber, providing excellent resistance to UV rays, ozone, and weathering. The reinforced version incorporates a strong fiberglass or polyester mesh to enhance the membrane’s strength, flexibility, and puncture resistance. This membrane offers superior waterproofing, durability, and energy efficiency, making it ideal for commercial, industrial, and residential applications.

2. Key Features

• Reinforced Strength: The inclusion of fiberglass or polyester reinforcement improves the tensile strength, flexibility, and resistance to punctures.

• Excellent Waterproofing: TPO membranes provide excellent waterproofing, ensuring protection against leaks and water infiltration.

• UV and Ozone Resistance: Exceptional resistance to UV radiation and ozone, extending the life of the membrane in outdoor environments.

• Energy Efficiency: TPO membranes reflect sunlight, helping to reduce heat absorption and energy costs by improving thermal insulation.

• Easy Installation: The TPO membrane is easy to install through various methods, including heat welding, adhesive bonding, or mechanical fastening.

• Environmentally Friendly: Made from recyclable materials, the TPO membrane is a sustainable option for modern construction.

3. Applications

• Roof waterproofing in commercial, industrial, and residential buildings.

• Foundation waterproofing for basements and underground structures.

• Waterproofing for walls, decks, and balconies.

• Suitable for both new construction and renovation projects.

4. Installation Process

1. Surface Preparation: Clean and dry the surface to remove debris, dust, and contaminants.

2. Unroll the Membrane: Unroll the TPO membrane onto the prepared surface.

3. Heat Welding or Adhesive Application: Use heat welding or adhesive bonding to secure the membrane, ensuring a strong and permanent bond.

4. Seam Sealing: Overlap the seams and use heat or adhesive to create a watertight seal between them.

5. Final Inspection: Check the installation for any defects, gaps, or air pockets to ensure a complete waterproofing system.