1. Product Overview

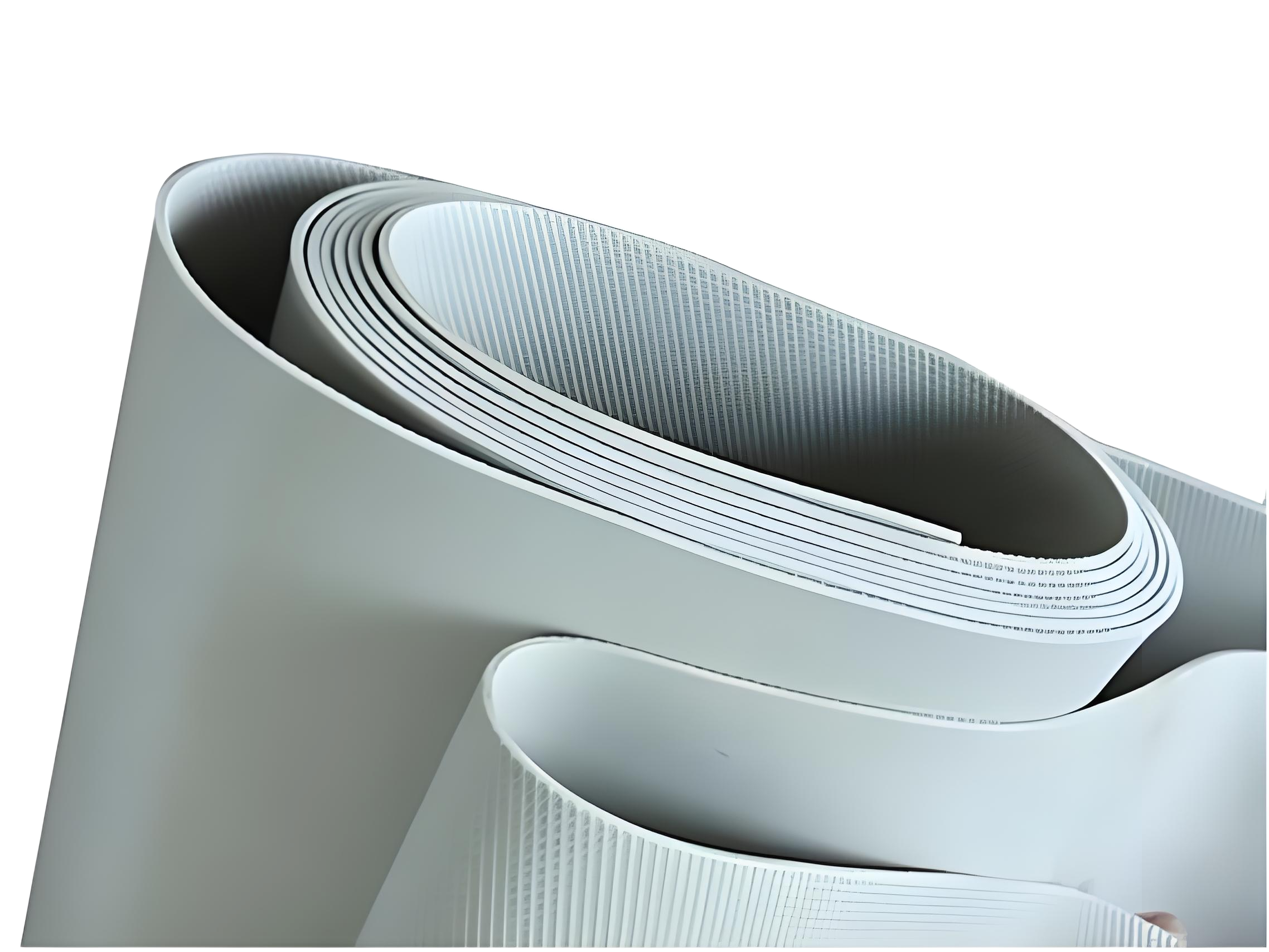

The Polyvinyl Chloride (PVC) Root-Resistant Waterproof Membrane is a specially designed high-performance waterproofing material that effectively prevents root penetration while providing excellent waterproof protection. It is made from premium-quality PVC material with additional root-resistant additives, ensuring long-term durability and resistance to plant roots. This membrane is widely used in green roofs, garden roofs, underground waterproofing, and other applications where root penetration resistance is required. Its high flexibility, weather resistance, and ease of installation make it an ideal choice for modern construction projects.

2. Key Features

• Superior Root Resistance: Special root-resistant additives prevent plant roots from penetrating the membrane, ensuring long-lasting waterproofing protection.

• Excellent Waterproofing Performance: Provides a highly effective barrier against water infiltration, protecting structures from moisture damage.

• High Durability: Outstanding resistance to UV rays, ozone, aging, and chemical exposure, ensuring a long service life.

• Flexible and Adaptable: High elasticity and tensile strength allow it to accommodate structural movements without compromising performance.

• Easy Installation: Can be installed using various methods such as hot air welding, adhesive bonding, or mechanical fastening.

• Environmentally Friendly: Free of harmful substances such as plasticizers, chlorine, and heavy metals, making it safe for green roof applications.

3. Applications

• Green roofs and rooftop gardens requiring root-resistant waterproofing.

• Underground waterproofing for basements, tunnels, and underground structures.

• Waterproofing for foundations, terraces, and balconies exposed to vegetation.

• Suitable for both new construction and renovation projects.

4. Installation Process

1. Surface Preparation: Ensure the surface is clean, dry, and free from dust, oil, or debris.

2. Membrane Placement: Unroll and position the PVC root-resistant membrane on the prepared surface.

3. Seaming and Bonding: Use hot air welding or adhesive bonding to securely join the seams and prevent water infiltration.

4. Edge and Detail Treatment: Seal edges, corners, and penetrations carefully to ensure complete waterproof protection.

5. Final Inspection: Conduct a thorough inspection to verify seam integrity and overall installation quality.